Japan [Niigata] Beyond ordinary itinerariesvol.3 Niigata prefecture Tsubame-Sanjo

The place for Artisans who breathe life into their craft

2017.04.06

Mr. Etsuji Yamazaki, the president

If you say you are going to Niigata, nine out of ten Japanese would say, “Oh! You are going to ski!” In fact, there are 48 ski resorts in Niigata, which is third highest number of ski resorts in one prefecture following Nagano and Hokkaido (from the data of 2017, “SNOWNET”). Niigata is also well known as the place where the highest numbers of swans come to spend the winter in Japan. From the beginning of October swans are seen and the number of swans reaches over 5,000 at the end of November. They stay until April and then fly back toward Siberia.

This time we head for Niigata via the Joetsu-Shinkansen to look for interesting attractions beyond ordinary itineraries associated with Winter or snow.

The Tsubame-Sanjo area

From ancient times there exist a general idea of Tsukumo-gami (trans. ninety-nine gods), which means a god dwells in objects that have been used for a long time. This god manifests in terrible way if the object it dwells in is treated roughly, but it also shows gratitude and grants favours to the objects owner if treated with respect and care. This concept is one of the features of traditional philosophy in Japan. When there were no machines, all objects were hand crafted with a lot of thought and effort put into their creation. Objects such as tools were made by craftsmen with the utmost care to ensure that it could be used for long a time, through generations. Thus, people loved and took good care of things just like how they loved and took good care of people. The philosophy of Tsukumo-gami may have developed as a way to teach people how to behave towards each other and objects. The objects created with tender care of an artisan were regarded as precious as if it were a baby born from loving parents. Now, much weight is laid on efficiency and mass production, which means that, regrettably, craftsmanship has put aside. That said, there is still a great respect for artisans in Japan, and Japanese people still cherish their possessions and take good care of things. The concept “Mottainai” (trans. a term conveying a sense of regret concerning waste), which became world famous when a Kenyan environmentalist introduced it at a session of the United Nations.

We would like to introduce the area called Tsubame-Sanjo, where traditional craftsmanship is still alive.

Since 2013, a four-day event called “Tsubame-Sanjo Factory Festival” is held during Autumn in the Tsubame-Sanjo area in the Niigata prefecture. Factories are open to the public during this event so visitors can visit to see artisans at work and experience some processes involved in the production of local goods. In 2017 it will be held from the 5th to 8th October. We visited, in advance to this festival, some of the factories that are open to the public all year round.

We got off at Tsubame-Sanjo station. Tsubame-Sanjo is just a name of the station, and does not correlate with the name of any nearby place. Sanjo is the name of the municipality where the station is located, while Tsubame is the name of neighboring municipality. In the early 17th century farmers of the area suffered as the river often overflowed. To solve this problem, the local governor invited skilled craftsmen who specialised in nails to teach the farmers their craft. Since then farmers made nails as a side-business and as a result had a financial back-up plan when the overflowed river damaged their cropland. Once the forging technique was developed, blacksmiths who created sickles, saws, and kitchen knives appeared. Thus this area became famous as “the town of forging”. Even though the area is divided into two municipalities, they gather to corporate with each other to protect the local industry. So, the name of the station is a symbolic for this corporation.

In the station premises, we found a neatly displayed shop named “Tsubame-Sanjo Wing” where many kinds of regional products and souvenirs are sold. Faces of craftsmen from Tsubame-Sanjo woven into hanging tapestries appeared to be almost inviting us on a trip to discover the craftsmanship in the area. The tourist information is also available at the information desk.

In this trip, we were able to see craftsmen at work putting their heart and soul into objects. The sprit, philosophy, and passion of all the people who were involved in the factory from the time of its establishment till now are reflected in finished products. The products are animated with the soul of the craftsman and they seem to be waiting for someone who use them and love them. Through this, we understood the real meaning of “value”, and the importance of tender care towards objects. In the area of Tsubame-Sanjo there are seventeen factories which are open for the public all year round. “Tsubame-Sanjo Factory Festival” is a good occasion to visit factories, however even if you can’t make it at this time we highly recommend you to visit factories in this area to have a once in a lifetime opportunity to witness traditional Japanese craftsmanship.

Gyokusen-do, Hand-Hammered Copper Ware

Tsubame-shi is known for its metal works internationally. Among many factories of metal working Gyokusen-do is the leading hand-hammered copperware making factory. Its 200 years of history started when the founder learned the technique of making hand-hammered copperware in the beginning of the 19th century. He made daily copperwares like kettles.

After Japan opened its gate to the world at the end of 19th century, it began to promote its high quality products to increase exports. Gyokusen-do was always included in this endeavour and even exhibited their products in Vienna World’s Fair in 1873, World’s Columbian Exposition in 1893, Japan-British Exhibition in 1910 and so on. In every exhibition Gyokusen-do was highly regarded for the beauty of its products and sophisticated techniques.

The factory is in a building built in the beginning of 20th century, which is now a registered Tangible Cultural Property. One step inside the gate will make you feel as if you were transported through time.

Hand-hammered copperwares are called Tsuiki-doki in Japanese. We were fortunate enough to witness the production process for teapot making. A skilled craftsman hammered a copper plate many times to make a three-dimensional shape. Normally a spout is made separately and is attached later with melted tin. But we saw a very special technique where the craftsman produced a whole teapot, even a spout. Surprisingly, he created a teapot without looking at a design drawing. He just hammered and hammered following the design plan that he had in his brain. The technique of hand-hammering is just like a magic. You may imagine that the copper gets thinner and wider when it is hammered. However, in reality the copper plate just diminishes in size when hammered.

The room where craftsmen work has a high ceiling for acoustic reasons so as to prevent the clanking sound from reverberating. The windows are large enough to let natural light in. We noted that each craftsman has his own rhythm and the way of hammering. As one craftsman makes one product all by himself, it is distinguishable to the trained eye who created the product. While watching a craftsman hammer a copper plate, we felt as if we had witnessed the moment when an aura or spark of life enters into an object.

The iron hammer is custom-made by a blacksmith in Sanjo-shi. One clank after another. A craftsman put his heart and soul into a product.

Marks made by an iron hammer become the pattern of the products. In other words, the skin of the products is made by a hammer. The soul and the spirit of the two craftsmen- the one who made the hammer and the one who uses the hammer to make the object- dwell in the final products.

Gyokusen-do

2-2-21 Chuo-dori, Tsubame-shi, Niigata-ken

☎ 0256-62-2015

Open: 8:30-17:30

Closed on Sundays and bank holidays

Access: 5 minutes by car from Tsubame-Sanjo station of Joetsu-Shinkansen, or 3 minutes on foot from Tsubame station of Yahiko-line.

Yamazaki Kinzoku Kogyo, Cutlery

Yamazaki Kinzoku Kyogyo (trans. Yamazaki metalworking factory) has been a leading factory of cutlery in Japan. Its history dates back to 1918, the year when World War I ended, when the founder set up a small factory of handmade spoons after he learned the technique of making hand-hammered copper ware. Their products are highly valued also in the overseas market. They supplied cutlery for the gala dinner which celebrated the 90th anniversary of Nobel Prize. Their factory is open for public only during the four days of “Tsubame-Sanjo Factory Festival”, but as an exception to this rule we were allowed to see the factory and the showroom.

Mr. Etsuji Yamazaki, the president

The history of cutley in Japan started after the country opened its door to the world and its domestic lifestyle slowly gravitated towards Westernisation. Before that, chopsticks were the only tools used at the dinner table. Thus the first clients of Yamazaki were Westerners who were living in foreign settlements such as Kobe and Yokohama. In the 1960s when the custom of using knives and forks were still not common among ordinary Japanese people, Yamazaki visited 65 countries in the world to develop sales channels. As he spread the philosophy of precise product making all over the world, his cutlery became highly valued in Europe and the US, the homelands of cutlery. Now almost every household in Japan has knives and forks. In Tsubame-shi, where about 90% of Japanese cutlery is made, Yamazaki Kinzoku Kogyo plays a leading role.

The beauty of the design, the texture felt in your hands, and the texture felt on your lips and tongue...these are the key elements that differentiate good cutlery from bad ones according to Mr. Yamazaki. In fact, cutlery has three roles: Cutlery set on the table should be beautiful and inviting as the main character;. When dishes are displayed on the table, cutlery should enhance their appearance to ensure the place setting looks civilized and gorgeous; And when are actually in use, they must dominate their users sense of taste. Even a very beautiful fork cannot be qualified as a fork of high quality if a user’s lips identify the metallic feel or taste. Low-priced cutlery is made through about ten processes, while in this factory there are about 35 or more than 50 depending on the designs. Although cutlery is not a traditional Japanese tool, the cutlery of Yamazaki is truly a “Made in Japan” product, crafted with extra care and great expertise.

Yamazaki Kinzoku Kogyo

2570 Oomagari, Tsubame-shi, Niigata prefecture

Factory is only open to the public during the Factory Festival

Tadafusa, Knives

In famous Kappabashi, Tokyo, which is known as “a kitchenware town” where there are hundreds of shops selling various kinds of kitchenware, many tourists who buy Japanese knives are seen. Culinary experts regard the superior quality of Japanese knives internationally.

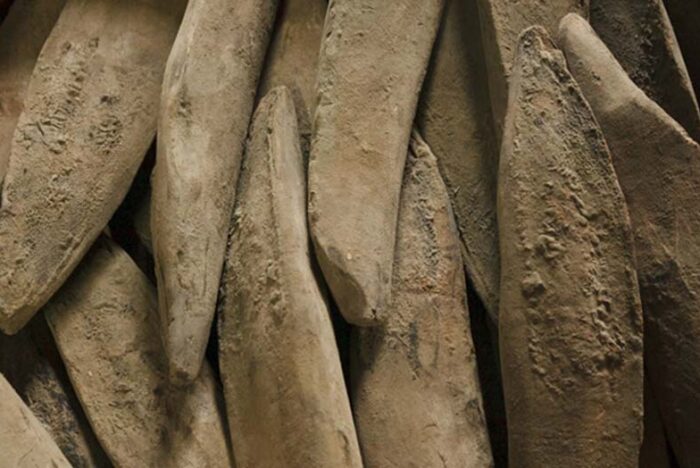

Tadafusa started its history as a knife-maker in 1948, soon after the World War II ended. At the beginning, they made mainly sickles, short swords and kitchen knives but their product range soon broadened and they began make various kinds of knives corresponding to the purpose of use as knives for fishermen, kitchen knives for household, kitchen knives for professional cooks, kitchen knives for soba makers . Soba are Japanese noodles made with buck wheat and it is like Italian tagliatelle in that it is made by cutting the dough with a knife. Soba making requires a heavy, straight and long knife. Tadafusa has produced and sold all kinds of knives imaginable suited to the purposes of their users.

In a showroom with a modern design that reminds us an atelier where artists work, various kinds of knives are displayed like art works. Some of them have “strange” shapes. It is an amusing game to imagine the purpose for which they were made. All the characteristics are meaningful, which are solutions developed by the skilful craftsmen of Tadafusa for the problems and challenges of their clients. Cutting is an action to divide or to make something smaller or thinner. It may also be used for breaking. Looking at every piece of a knife, however, you can be astonished to realize that the actions of human body and the intentions are different depending on what one is trying to cut. To be precise, the degree of pressure and motion involved in cutting change depending on the size, the shape, the hardness, and thickness. Also, the skill-level of user, professional or novice, would be another key factor. These knives are artworks created craftsmen who put themselves in users’ shoes, which is the spirit of Japanese craftsmanship!

As eating habits in Japan are now Westernised, bread knives are not so rare in many households in Japan. Normally their edges are all wavy and serrated, but the bread knife of Tadafusa is different. Just for a few centimeters the tip is serrated and other part is flat just like normal knives. This bread knife was made for Japan’s bread culture. Even though hard-crusted bread is popular in Japan now, the bread mainly preferred is shokupan (trans. bread for meal), a soft and white square shaped loaf. In supermarkets shokupan is usually sold already sliced. Those who appreciate high quality bread prefer to buy a loaf in bakeries and cut them by themselves. As shokupan’s crust is soft and the inner part is even softer, if sliced with a blunt knife the bread will be pressed or with a serrated one its surface will become rough. This is where Tadafusa’s bread knife comes in. Its serrated tip holds the soft crust and its sharp edge goes through the bread so smoothly. You should try using it at Tadafusa’s showroom. You will know how pleasing the sharpness of a well made knife is.. This knife is also recommended for cutting soft things with skin such as tomatoes.

“Strike while the iron is hot.” This is a famous idiomatic phrase which is also used in Japan. Here in Tadafusa’s factory, you can see craftsmen striking red-hot iron. They operate a hammering machine by foot and carefully watch the state of the iron. It is as if the spirit of craftsmen who know that sharpness will bring happiness to users is pumped into the knife with every pound of a hammer.

Tadafusa, atelier of kitchen knives

27-16 Higashi-honjoji, Sanjo-shi, Niigata prefecture

☎ 0256-32-2184

Open: from 8:00 to 17:00

Factory tour: from 10:00 to 11:30, from 13:30 to 16:00

Marunao, chopsticks

Chopsticks are also good souvenirs of Japan among foreigners. Now Japanese cuisine is popular in overseas many people are getting accustomed to eating with chopsticks. Japanese people are known to be clever with their fingers, which is probably because they use chopsticks. Chopsticks, however, run the gamut from disposable ones to ones of high quality. Here in Marunao, you will know the best of chopsticks and witness the process for their production.

The founder of Marunao was a craftsman who started his career creating wood-carvings for Buddhist wooden cabinets. At the time of the foundation of the company in 1939, they offered wood-carvings to temples and shrines. Lately, they make mainly chopsticks using ebony and rosewood. These wood types are hard and traditionally used for furniture, including Buddhist wood cabinets. Marunao also makes and sells wooden spoons, wooden espresso cups and stationery with the unused sections of wood remaining from chopstick production. In their modern style shop, which is cool and simple like a luxurious boutique, fine and delicate chopsticks of the highest quality are displayed.

In the factory you can see how craftsmen work through a glass window. Chopsticks are made, one by one, by scraping a piece of wood. The thinness and the shape of the chopsticks are key to a successful design. The tip and the base are made into an octagon, while the centre part is made into a hexadecagon. This is the ultimate shape of chopsticks, which has been developed with through a desire to optimise their functionality. The chopsticks with flat shape and eight sides make it easy to pick up even small and unstable pieces of food.

The chopsticks of Marunao are also light. When you hold them they fit comfortably in your hand. If you eat traditional Japanese dishes like sashimi (trans. slices of raw fish) using these chopsticks, you will know the real meaning of Japanese cuisine, which places importance on the delicacy of picking up small portions of food.

Marunao

1662-1 Yada, Sanjo-shi, Niigata prefecture

☎ 0256-45-7001

Opening hours of shop: from 10:00 to 19:00

Factory tour: form 9:00 to 17:30

About the project “Beyond ordinary itineraries”

vol.1 The Chichibu area in Saitama prefecture

A great attempt to make a new tradition in the Chichibu area

-Venture Whisky, Ichiro’s Malt-

A great attempt to make a new tradition in the Chichibu area

-Maple Base-

A great attempt to make a new tradition in the Chichibu area

-House of Miyamoto, an old farmhouse-

A great attempt to make a new tradition in the Chichibu area

-Chichibu Meisen House-

(The Chichibu area in Saitama prefecture Booklet PDF)

(The Chichibu area in Saitama prefecture Booklet PDF [for printing])

vol.2 The Hokuso area in Chiba prefecture

Tradition - inheriting the spirit and soul-

(The Hokuso area in Chiba prefecture Booklet PDF)

(The Hokuso area in Chiba prefecture Booklet PDF [for printing])

vol.3 Niigata prefecture Tsubame-Sanjo

The place for Artisans who breathe life into their craft

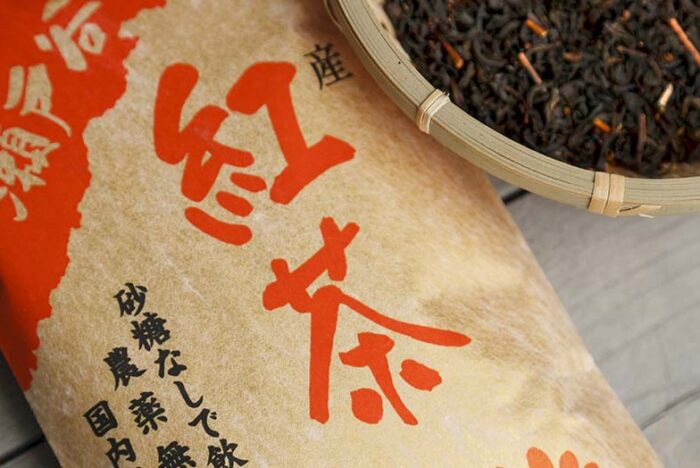

vol.4 Niigata prefecture Niigata city

The Power of Fermentation Can Also Connect People, Events and Products

(Niigata prefecture Niigata city&Tsubame-Sanjo Booklet PDF)

(Niigata prefecture Niigata city&Tsubame-Sanjo Booklet PDF [for printing])

vol.5 Kasumigaura and Mt.Tsukuba area in Ibaraki Prefecture

Fascination of the area is like a constellation, it comes out when the dots are connected.

(Kasumigaura and Mt.Tsukuba area in Ibaraki Prefecture Booklet PDF)

(Kasumigaura and Mt.Tsukuba area in Ibaraki Prefecture Booklet PDF [for printing])

This project is supported by the Kanto Bureau of Economy, Trade and Industry.